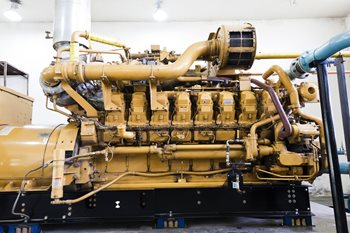

Cannabis Farms Use Industrial Generators For Operations

Most businesses do not think about an emergency backup power generator until it’s too late – they lose grid power and operations come to a halt. Utility power outages in the United States are more common than many business people may realize. In 2017, 36.7 million people were affected by power outages. These outages lasted an average of 81 minutes.

Depending on your organization’s size and business model, an hour without electricity could cost hundreds of thousands of dollars from ruined inventory, lost production, and risk to equipment. For these reasons, prepared organizations should invest and install reliable used backup industrial generators and to maintain those generators throughout those lifetime.

The Cannabis Industry Requires Used Industrial Backup Generators

Common characteristics of a business that would require a reliable backup industrial generator include:

Common characteristics of a business that would require a reliable backup industrial generator include:

- Large impact if the power went down causing a halt in operations. This interruption is quantified in resulting losses of revenue or jeopardized

- Low tolerance for short interruptions. While some operations (e.g., lighting) are quick to recover from an outage, others (such as computer systems or manufacturing equipment) may require extended reboots from a short outage.

- Underdeveloped utility grid. When businesses and manufacturing operations are established in new areas, many utilities may not be fully operational or fault tolerant for years.

Across many industries, sophisticated facility management requires backup industrial generators to maintain successful ongoing operations.

Organizations operating in remote or newly developed areas may not have ready access to the electrical grid. This circumstance is common among cannabis growers, as local regulators zone new areas for grow operations. Many pot growers utilize diesel generators in prime power applications to power their operations before grid power reaches their facility. An additional impact of newly developed areas is the slower speed of recovery (compared to densely populated areas) following a power outage. To prevent such problems from occurring a used industrial generator can offset these power losses and prevent any revenue loss from operations.

Cannabis Farms

Modern legal cannabis farming operations consume an immense amount of energy – in the form of grow lights, ventilation, processing equipment, and administrative systems. Most cannabis grown in commercial production will never see day light. Instead, the industrial grow rooms that use high-intensity lighting with strict air quality conditions. Though indoor cannabis farming originated in the back closets of illegal growers, commercial pot growers have industrialized the scale and efficiency of indoor farming.

Hemp cultivation to produce CBD (cannabidiol) requires equipment-intensive processing, requiring great amounts of energy. For example, an agricultural lighting fixture can use as much electricity as 29 refrigerators. When you start to scale this consumption to a 5,000 square-foot facility, the amount of power needed for operations is staggering. In areas with high grid electricity rates, the use of a dedicated used industrial diesel generator may provide a cost efficient to utility upgrades and costly electricity.

Downtime is a big problem for the cannabis industry due to the sensitivity of crop to changes. A farm-raised cannabis plant needs 18 - 24 hours of light each day in order to keep growing and healthy. If the plant receives less than 18 hours, it can flower early and reduce the yield thereby decreasing the downstream revenue. Since cannabis growth is dependent on the light it receives, power outages slower growth, increase production costs, and suppress profitability.

The supply chain for the cannabis market is broken down into three domains: Cultivation (growers), Manufacturing, and Retail.

CULTIVATION

Cannabis cultivation generally consists of climate-controlled grow houses where cannabis plants are grown from seed into mature plants. In warmer climates, outdoor growing (similar to traditional farming) can be common and economical. In cooler climates, especially in higher latitudes, green houses are generally used. Modern grow houses include irrigation systems, climate control, and industrial lighting, all of which are sensitive to power outages.

Cultivation is where having investment in an industrial used generator makes the best business. At the cultivation stage the product is being created to eventually be sold at the retail level. Cultivating cannabis is a complex, energy intensive process. For example, adequate heat is critical to the successful cultivation of cannabis and missing just one sun cycle can destroy an entire harvest. The risk of potential crop loss due to power interruptions should lead advanced cannabis operators to establish backup power systems.

MANUFACTURING

Manufacturing is the next stage in the cannabis value chain, where the raw plants are transformed into consumer products. These manufacturing facilities are highly secure and involve the production equipment to produce a number of different products, such as oils, gummies, and smokable weed. To manufacture consistent cannabis products, cannabis companies perform oil extraction, flower clipping and drying, packaging, product tracking, and final product storage / refrigeration. Due to legal restrictions and the high street value of the products, cannabis production facilities require significant security and monitoring equipment.

The equipment at oil extraction facilities generally has a low tolerance for grid interruptions and can benefit from investment in backup power solutions. Generators can provide either backup or prime power to the manufacturing operation, depending on the level of grid development at the production site. When used in an emergency backup power situation, diesel or natural gas generators are linked to an ATS (automatic transfer switch) and in some cases a UPS (un-interruptible power supply) to automatically provide electricity during a grid failure. In locations with underdeveloped electrical grids, prime power generators are the on-site primary source of electricity for the facility.

RETAIL

The final stage in the cannabis supply chain is retail to end consumers through pot dispensaries. These dispensaries house finished product and display it for sale to consumers. One of the primary concerns in dispensaries is the security of the valuable products. Dispensaries are generally found near population centers and have reliable power. Though not as important as other steps in the value chain, backup power for security and surveillance systems can benefit from the installation of a backup generator. These generators are commonly smaller than those that support the other two steps and their sound attenuation isolates the noise of generator exercises and usage from nearby neighbors.

If you’re interested in buying a used industrial generator from Generator Source please fill out a contact form or give our company a call!

Kyle Smith

| 11/10/2020 4:17:55 PM

|

0 comments