Generator Source has been providing new surplus and used commercial and industrial generators for over 30 years. Our facilities (Figure 1) feature:

- 25,000 ft. Shop/Office and Generator Warehouse

- 10,000 ft. Customization and Fabrication Shop

- Shipping & Receiving hut and Stoarge Yard

Shop/Office Warehouse

The office, shop and warehouse are contained into one 25,000 ft. building. When a customer arrives at our new facility, they are greeted by a receptionist and routed to the appropriate staff member. Our offices are located throughout the building. The shop is large enough for us to use it as a warehouse. Many small and medium generator are stored here as well as larger critical parts.

62d2.jpg)

Figure 1, Shop/Warehouse/Cranes

The shops are split into two sectors divided by an office structure. We have the capability to move and place large generators anywhere in the shop using two bridge cranes. The 20 ton bridge crane allows overhead operation for approximately 75% of the shop area. A 5 ton bridge crane supplies coverage for the remaining bays.

The buildings are located on 14 acres of land that is surrounded with security fencing. The fenced yard provides storage for large and enclosed generator sets.

To illustrate the services our shops provide, this article will track the process of a generator from the time it is received (initial purchase) until the time it is ready for sales to the customer. Equipment and shop capabilities used in the following processes are:

- Shipping and Receiving

- Standard Inspection and Testing

- Customization and Fabrication

- Services

- Shop/Office Warehouse

Figure 2, Generator Source Facilities

Shipping and Receiving Generator

We purchase commercial and industrial standby generator sets with low hours. Once the generator arrives at our facility, it’s checked in at the Shipping and Receiving hut. The truck is routed to the generator staging area where it’s unloaded. A 55,000 lb. fork truck and a 40,000 lb. standard yard crane are available loading and unloading operations (Figure 3). For larger sets we have crane vendors ready to assist. Once the generator passes our inspection, all yard equipment and services are available for worldwide shipping to the customer.

Figure 3, Fork Truck and Standard Cranes

Standard Inspection and Testing

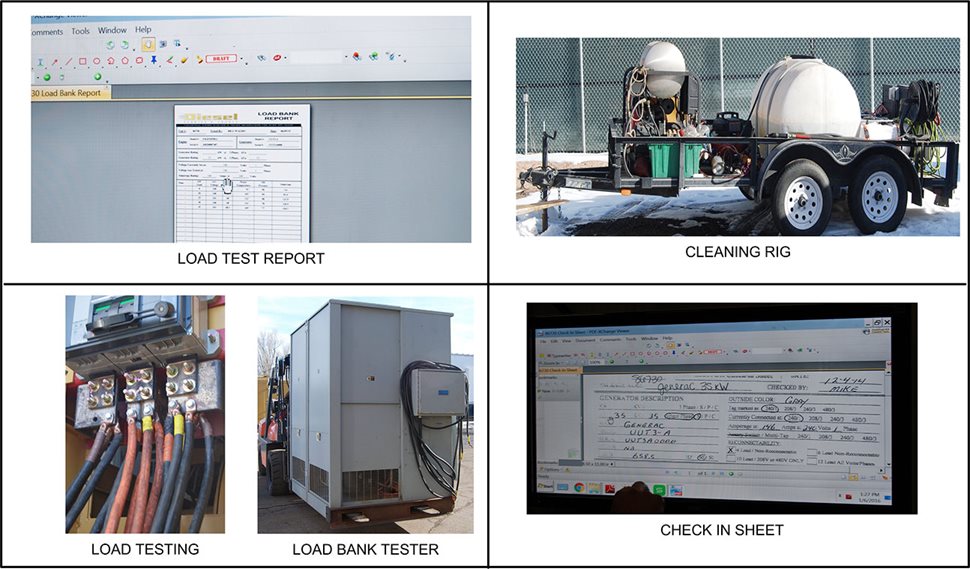

All of our generator sets are guaranteed to meet manufacturer specifications (Cummins, Caterpillar, Baldor, etc.).Small (less than 20,000 lbs.) and Medium (20,000 lbs.) are used in moving test equipment for maintenance of generator sets. Each generator set undergoes the following (Figure 4):

- Cleaning and Painting – Generators are thoroughly cleaned prior to inspection. Paint services are utilized as needed.

- Inspection – Each generator undergoes a 31 point inspection. Any repairs needed are completed by our Customization and Fabrication Shop to obtain certification.

- Results of the inspection are recorded on the check in sheet - The check in sheet is downloaded into shop software.

- Load Bank Testing – Numerous brands and styles of load testers are maintained on site. The selected load bank tester is connected to the generator and it’s loaded to manufacturer specifications. A Load Test Report is generated and maintained in shop software.

- Oil Analysis- Each generator has an oil sample drawn. The analysis is performed in shop or we have partners that can provide the results in short order.

- Battery Testing and Inspection – All generator set batteries have specific gravity and load test completed as a part of the initial inspection. A low or failed battery cell is a major component when checking Engine Does Not Crank complaints.

Figure 4, Check In and Load Testing

Customization and Fabrication Shop

The Parts and Service office is located in the mezzanine of customization and fabrication shop (Figure 5). This office controls acquisition of parts and all maintenance and service activities.

All service, maintenance and customer upgrades are maintained electronically by technical staff. A “commonly-used” parts supply is maintained to insure timely processing of generator sets.

The shop is staffed with the industries top fabricators, mechanics and technicians. The fabricators provide industry standard fabrication services to include:

- Spot and General Welding – Often generator set enclosures suffer damage during transport to our site. We repair damages and supply paint services after repair.

- Enclosure Door and Panel Fabrication – We have the ability to fabricate door and panels for any generator enclosure. We perform this service on enclosures with components that are damaged beyond repair or missing.

- Fuel Tank – Shop has ability to repair or fabricate fuel tanks for enclosed generator sets.

On-staff technicians utilize the best tools industry has to offer to provide technical support required to complete Services tasks. The Shop offers mobile services with the addition of a service trailer equipped for remote repairs.

Figure 5 Customization and Fabrication Shop

Services

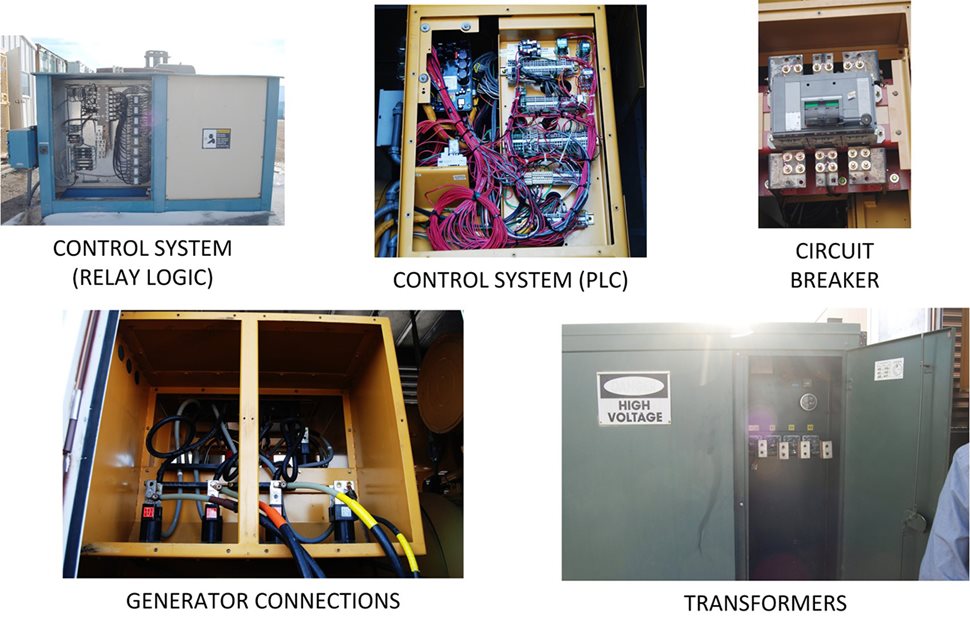

A wide variety of services are provided to assist customers with all of their power generation needs. These services range from upgrading dated systems to changing system operating specifications (Figure 6). Below is a list of services we offer:

- Control Panel Installations and Upgrades – When a generator’s control system is considered to be “dated” (relay logic system), we can upgrade it with a new control system (PLC controlled). We work with all major brands including Deep Sea Electronics, Woodward Controllers, CAT EMCP and Cummins PCC panels.

- Voltage Changes – It is common practice for our technicians to change the voltage on large industrial generators. The internal wiring of the generator controls the ability to change voltage outputs. Step-up or step-down transformers can be used to adjust voltage to required needs.

- Frequency Changes – We have the ability to change frequency from 60 Hz to 50 Hz for international customers that require it. Some generator sets offer the ability to change engine speed to change frequency. In some instances third party components, such as frequency converters are used.

- Phase Conversions – For generators below 250 kW we can often change single phase to three phase and three phase to single phase. Not all generators have this ability.

- Electric Components – We commonly change generator ends, voltage regulators (older generators) and circuit breakers.

- Sizing Requirements – Our staff can assist in generator and support system sizing requirements.

- De-installations Services – Technicians can remove customer old generator and install new generator and components.

Figure 6, Services Offered