Generator Grounding

Occupational Health and Safety Administration (OSHA) requires all combustion engine driven generators be grounded to the earth. This includes both stationary and portable models serving emergency, prime and continuous applications.

Occupational Health and Safety Administration (OSHA) requires all combustion engine driven generators be grounded to the earth. This includes both stationary and portable models serving emergency, prime and continuous applications.

Impedance grounding the generator has both safety and equipment benefits listed below:

- Reduce burning and melting effects in electrical equipment (switchgear, transformers, cables and rotating machines) during ground fault

- Reduce mechanical shock in components and circuits that are exposed to ground fault

- Reduce electrical shock hazard to personnel who caused or in close proximity of ground fault

- Reduce line voltage dip that can occur when clearing ground fault

- Secures control of transient over-voltages while avoiding a facility shutdown

This article describes some common methods for grounding a generator. Transformer and capacitor configurations are used in the impedance grounding configurations. The transformer configuration is featured. This is a general guideline, you should always consult a certified electrician or electrical contractor to make sure you end up with safe and properly grounded generator set prior to operation.

The direct earth grounding method is the simplest method. In this method, the grounding wire or strap is attached to the alternator on one end and an earth ground on the other end. This method is used in small portable generator applications.

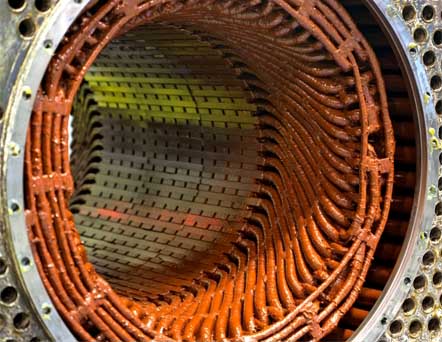

Impedance grounding configurations are generally used for larger applications. Impedance is defined as the total resistance the circuit offers when energized. Components that offer resistance in grounding circuits are transformers, conductors, grounding rods, and electronic components.

Low Impedance Grounding

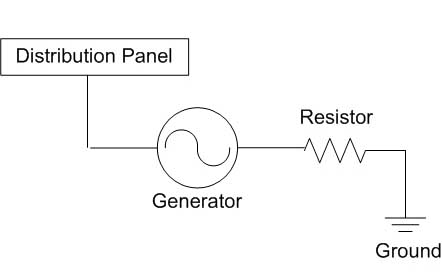

A resistor is installed between the generator and grounding rod. This resistor is called a neutral grounding resistor. The grounding resistor limits the fault current when one phase of circuit shorts or arcs to ground.

The resistors commonly limit current from 200 to 400 amps. Many resistor manufacturers classify any resistor that limits current to 25 amps or greater as low resistance. An example of resistor specification is 1200V L-N, 200A 10 seconds. This resistor's impedance allows 1200 volts with 200 amps of current for 10 seconds before overheating.

Grounding resistors can handle 10% of their rated load continuously. A 200-amp resistor can handle 20 amps continuously without overheating. Over current devices can be installed in the circuit to prevent resistor heat damage.

Some considerations when designing Low Impedance Grounding circuit are:

- Phase to ground currents limited 200 to 400 amps

- Reduces arching and arch flash hazards associated with phase ground

- Reduces damage to rotator and stator

- Does not prevent operation of over current devices

- Ground fault detection system is not required

- Can be used on medium or high-voltage systems

High Impedance Grounding

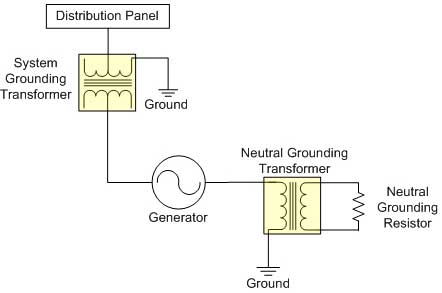

High impedance grounding circuits utilize a neutral grounding transformer for generator protection. Generator ground is connected to input of primary winding of neutral grounding transformer with a path to ground.

Neutral grounding resistor is connected across the secondary windings of the neutral grounding transformer. The configuration uses the principle of reflected impedance which protects the generator.

System grounding transformer primary winding is connected to the generator. Secondary windings supply the distribution panel and supply path to ground in the event of a system fault.

Some considerations when designing high impedance grounding circuit are:

- Phase to ground currents limited 5 to 10 amps

- Reduces arching and arch flash hazards associated with phase to ground

- Eliminates damage to rotator and stator

- Prevent operation of over current devices until fault can be located

- Requires ground fault detection system

- Can be used on low or medium voltage systems

Compensated Grounding

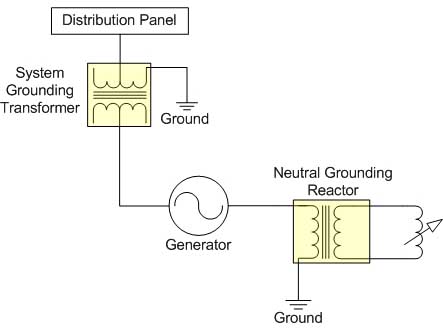

Compensated grounding systems can also be referred to as reactance or resonant systems. This system is designed much the same as the high impedance system.

System grounding transformer primary winding is connected to the generator. Secondary windings supply the distribution panel and supply path to ground in the event of a system ground fault.

Neutral grounding reactor replaces the neutral grounding transformer and resistor used in high impedance grounding circuits. The reactor is a combination of a transformer with a Peterson coil attached to a grounding transformer. Peterson coil allows system tuning.

When system inductance and capacitance matches, the system is 100% tuned or fully compensated. If reactor impedance does not match capacitance, the system is turned off.

Some considerations when designing a compensated grounding circuit are:

- More expensive that high or low impedance system because of addition of neutral grounding reactor

- Uses system grounding transformer for system grounds

- Uses reflected impedance design as the high impedance systems

- No generator damage from ground faults

- Reactor is tuned against generator capacitance to ground. Ground fault currents can be less than 1 amp

Hybrid Grounding

Hybrid grounding systems are designed to allow for the benefits of both the high impedance and low impedance grounding systems. Ground faults accomplish minimal damage to generator and system components.

In the event of a generator ground fault, the system will utilize the high impedance grounding portion of the circuit to minimize generator damager. This system is safer for the generator because it is never left in the ungrounded state as with low impedance systems.

This configuration provides the benefits of low impedance systems because all ground faults will have selective coordination providing minimal damage at the point of the fault. Ground fault current is limited to the sum of the low impedance system.

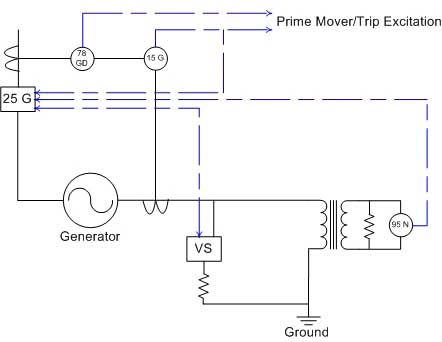

System Protection:

- 15 G is back-up protection for system machines that are connected to ground bus. If the machine is not connected to the main ground bus it will not be protected

- 15 G will not provide back-up protection for the generator because of timing

Generator Protection:

- Fault is detected by 78 GD

- Low impedance ground path is opened by switch (vacuum or air)

- High impedance path to ground is only one available

Additional Resources:

- NEC Requirements apply to standby generators permanently installed on buildings see this grounding article from NECA director of standards here.

- OSHA also has a nice fact sheet on Portable Generator Grounding Requirements and Safety.

Summary

All engine driven generator sets are required to be properly grounded. Smaller portable sets can have simple earth grounds. No protection to generator or devices are available with simple earth grounds. Impedance

grounding is popular on medium and large systems. This ranges from low to high impedance grounding with hybrid incorporating the capabilities of both. Compensated grounding is the most expensive but can be tuned to the circuit with the reactor. Once the proper system is selected, choose components to design system that are robust enough to handle configuration.