|

|

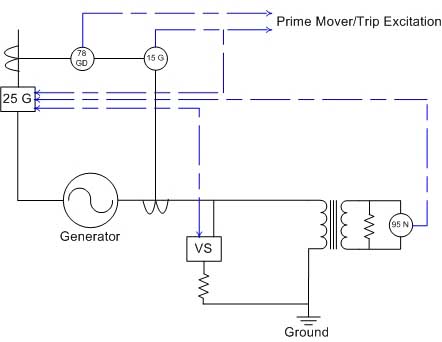

Generator Grounding Methods

Occupational Health and Safety Administration (OSHA) requires all combustion engine driven generators be grounded to the earth. This includes both stationary and portable models serving emergency, prime, and continuous applications. This month's article describes the common methods for grounding a generator including: low impedance grounding, high impedance grounding, compensated grounding, and hybrid grounding. Diesel Service & Supply helps customers select the proper generator to suit your needs and configure the proper grounding method required. Occupational Health and Safety Administration (OSHA) requires all combustion engine driven generators be grounded to the earth. This includes both stationary and portable models serving emergency, prime, and continuous applications. This month's article describes the common methods for grounding a generator including: low impedance grounding, high impedance grounding, compensated grounding, and hybrid grounding. Diesel Service & Supply helps customers select the proper generator to suit your needs and configure the proper grounding method required.

Click below to continue:

Click Here: Generator Grounding Methods

Follow Us For Inventory Updates, Videos & Informative Articles!

|

|

|

HiPower 590 kW (Trailer Mounted)

2012 Diesel Generator, 208/3 480/3 V

Voltage Selector Switch, 60 Hz

1665/208 721/480 Amps

901 Hours, Unit#: 87710

|

Kohler 400 kW

2007 Diesel Generator, 480 V

3-Phase, 60 Hz, 609 Amps, Standby

83 Hours, Unit#: 87766

|

|

Cummins 500 kW (Trailer Mounted)

2007 Diesel Generator, 480 V

3-Phase, 60 Hz, 752 Amps, Standby

3079 Hours, Unit#: 87749

|

Kohler 125 kW

2011 Diesel Generator, 208 V

3-Phase, 60 Hz, 430 Amps, Standby

112.8 Hours, Unit#: 87707

|

|

|

|

|

|

|

|

| Allison |

3100 kW |

| Cummins |

2000 kW |

| Caterpillar |

2000 kW |

| Caterpillar |

1250 kW - 4160 V |

| Cummins - 65 dBA Enclosure |

1250 kW |

| MTU |

1000 kW |

| Generac |

800 kW |

| Cummins - NEW (Natural Gas) |

750 kW |

| Cummins |

500 kW |

| MTU - NEW |

500 kW |

| MTU - NEW |

400 kW |

| Kohler |

300 kW |

| Kohler |

125 kW |

| Olympian |

100 kW |

|

|

|

|

|

|

|

|